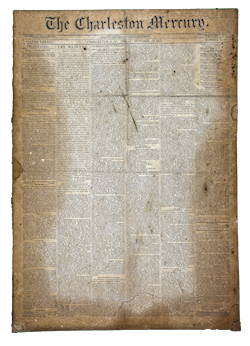

February 21, 1861; The Charleston Mercury

CASTING PROJECTILES.

Solid shot, case shot and shells are cast at ironworks from white forge iron; formerly iron moulds were used for these, but they had the effect of making the balls too hard on the surface, whereby the bore of the gun was injured. At present, therefore, all projectiles are cast in sand in mould boxes. The casting of solid balls is the most simple. The patterns for this purpose are of brass, very exactly turned, made in two halves, and fitting into each other by a groove; one half has a pin screwed into it, which forms the hole by which the metal is poured in at the casting. In moulding, the grooved half of the pattern is set upon the mould board, and the tap hole pin screwed in; there the mould box is placed with its keybolts in the holes made for them, and the half ball moulded by the sand layer. The mould is then turned over, the mould board taken off, the second half ball set on, the second mould box placed, and the mould made in the same way; then the mould is turned, the pin screwed out, the mould box opened, and both patterns taken out, when it is again closed and is then ready for casting.

The mould of the hollow shot is more complicated, because the internal cavity of these must be formed by a core, which remains in the mould during the casting, and is removed afterwards; and because, also, for the larger sizes, a pair of ears must be cast in, for the shell hooks to catch hold of in handling them. For hollow shot it is preferable to have the metal run into the mould at the side, so that the core be not disturbed in its position by the metal falling perpendicularly upon it; this core is made of sand or loam; the ears are of wrought iron, and the ends reach into the internal cavity, where they are afterwards imbedded in the metal.

MILITARY PYROTECHNY.

The manufacture of cartridges of all kinds, and of fireworks generally, especially fire and light balls and rockets, for military purposes, is the object of a particular art – that of military pyrotechny.

Musket cartridges consist of a piece of paper, one side of which that it may wind more closely, is cut obliquely; this leaf is rolled about a former, the ball set in, and the throat choked with a tie of linen thread, and struck down upon the ball, then the cartridge is filled and pinched together at the top, and is ready for use.

Cannon cartridges are made of flannel bags almost entirely; for marking out the form upon the piece of stuff, the pattern board is used. Each calibre has a certain sized pattern board. The length of the cartridge depends upon its being designed to hold the ball or not. When the bag is sewed with the back stitch, turned and felled, the sabot, which has a groove, is set in, the ball is placed on the sabot, and then the head is tied. Afterwards the ball is fastened to the sabot by two strips of tin, crossing each other at right angles, the bag being secured to both.

THE ‘MORTAR’OF THE ANCIENTS.

As far back as 1328, the French had short cannon called ‘Bombards.’ They were first made of wood, with iron hoops, and lay upon a roller carriage; they were afterwards lined with iron plate, strengthened with bars of iron, running lengthwise the barrel, and bound with iron hoops. But as even this could not withstand the force of powder, they constructed them of forged iron, cast iron, and finally of bronze. All the bombards or mortars shot only stone balls, or fragments of iron, and it was not until the year 1400 that iron balls were used.

SFORZA had, before Placenza, in 1447, three Bombards; each of which discharged, in twenty four hours, sixty stone balls, and with which, in thirty days, he battered down two towers and the wall between.

IMPROVED MORTARS OF THE PRESENT TIME.

Mortars are in some respects like howitzers, save that the trunnions, since they are only designed to discharge shot at a very great elevation, are not in the middle but at the hinder end; there are some, indeed, which have, instead of trunnions, only a cast foot, and which can, therefore, be only fired at one angle. Mortars are most usually distinguished by the diameter of the iron shell which fills the bore – thus we speak of ‘, 10 or 12 inch mortars,’ the latter of which throws a shell of about 100 pounds weight. The internal arrangements of the mortar are very different from the cannon. The charge of powder is very small in comparison with the size of the shot, and is compressed into a small chamber made for it in the breech, terminating in the hemisphere. The forward part of the bore, the chase, receives the shell in loading, unites with the chamber by a segment of a sphere, and is called the seat of the shell. From thence to the mouth of the bore is cylindrical, and is called the cylinder.’

MORTAR CARRIAGES OR BEDS.

For mortars which have their trunnions on the second reinforce, the so called hanging mortar, the carriage consists of two checks, connected by bolts and transoms, but these are now little used; the carriage mostly used is, a short massive block of wood, seasoned oak is the best – upon this bed is hollowed out the place for the trunnion bed and the foot of the mortar. The lower corners of the bed are notched in, to allow of handspikes being thrust under for moving it upon the platform. On the trunnion of the mortar an index is fixed, which shows upon a circular scale, attached to the bed, the angle of elevation.

THE ELEVATING SCREW.

With mortars the muzzle must be movable through a curve of from 10 to 60 degrees, in order to give the necessary elevation or depression for the aim. To effect these movements with the requisite accuracy and rapidity, the elevating screw is applied, although the simplest means of accomplishing the purpose is by the quoin or wedge, by moving it in or out under the base ring – there are generally three quoins or wedges employed. Under 15 degrees elevation, the mortar lies upon its bed, the first quoin gives 25 degrees, the second 30 degrees, and thus, with the third, 45 or 60 can be given. The screw quoin is better still, as it admits of more accuracy in the elevation. In all cases a wooden platform is laid, upon which the mortar and carriage is placed, to secure a level from which to regulate the firing.